Steel to make the plastic and the which you need to know

Steel making plastic commonly used are molding. The hardness of the steel is the direct factor that determines the strength of the mold. Learn about the types of steel used for plastic molds.

What is steel making plastic ?

Steel for molds used in the production of molds. Due to the variety of molds used. So Fengyang also diversified the properties, range of materials used by the steel to meet the needs of customers. We manufacture steel according to the standards as follows:

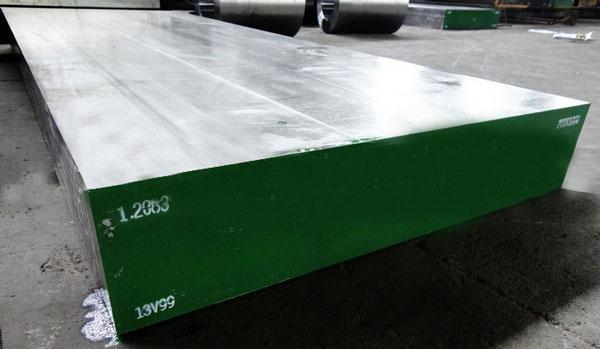

Steel grades:

DIN1.2083,1.4021,1.4028,1.2344,1.2343,1.2379,1.2312,1.23738,1.2085,1.2360,1.2581,1.2316,1.2085,1.2510,1.2367,17CrNiMo6,34CrNi3Mo, 36CrNiMo8, 718, 718V, WB36, …

US Standard: 420.410, H13, H13EFS, D2, P20 + Ni, P20 + S, O1, O2, H10, H11,4145H, 4340, P91, P92 …

Standard Japan and Korea: SUS420J2, SKD11, SKD61, SKD6, DC53, SKS3, SKS31, SKT4, NAK80, HMD, KP4, KP4M …

Standard DIN steel is our most competitive tool steel

Production Specifications:

Round steel: Φ3mm ~ Φ1000mm;

Square steel: 20mm – 1000mm;

Flat bar steel: thickness: 3mm ~ 800mm, width: 150mm ~ 1800mm;

Length: 2-5.8m or delivery according to the length required by the user;

Heat treatment technology: EAF + EAF + LF + VD + ESR

EAF Electric arc furnace

EAF Furnace

LF Vacuum Filter

VD Non-vacuum induction furnace

ESR Electric furnace

Delivery status: hot rolling, forging and tempering.

Surface treatment: black, grinding, polishing …

Steel ultrasonic inspection: according to SEP1921 standard, GB / T4162, GB / T6402, JB / T 4730, JB / T5000 standard or trial user,

For steel making molds, we mainly supply the following sizes:

Round steel: ⦽80mm ~ ⦽1mmmm

Square steel: ⦽80mm ~ ⦽1000mm

Steel bars:

Thickness: 80mm ~ 800mm

Width: 300mm ~ 1800mm

Length: 2 ~ 5.8m or can be customized according to customer’s specific length.

How to choose the best plastic molds

Choosing high-strength steel to increase mold life means increasing the cost of molding. This means that cost increases lead to higher costs. Therefore, depending on the requirements, we should choose the type of steel suitable for plastic mold.

For molds that do not require high precision, molding materials should be S50C, S55C, and Nak80 … these materials are reasonably priced, easy to find and easy to work with. For high-precision molds, plastic material containing abrasive materials such as glass requires high-strength steels such as SKD11, ELMAX, SKH51 …

If you are designing molds that require high durability. In order to minimize the cost of molding, it is best to divide the mold into two parts and use two different types of steel. You can use low hardness materials, soft prices. The core of the mold should use materials with high hardness to meet the technical requirements that mold prices are greatly reduced.

Refer to some special types of steel at FENGYANG:

Types of steel difficult to find in the market, is the strength of the company. There are two types of steel: cold rolled steel and hot rolled steel.

Forged steel

Alloy steel

Steel elastic

Stainless steel & stainless steel

Weather resistant steel & Corten