Buy elastic steel to do quality saw blade to pay attention?

Buying elastic steel as a quality saw blade, is always a problem that most mechanical manufacturers are always looking for. So where are the answers related to this issue, let’s learn through this article offline.

What is elastic steel?

Elastic steel is a particularly hardened steel with high elasticity, with a relatively high carbon content, in the range of 0.55-0.65%. Elastic steel used to make tweezers, springs and other elastic parts.

Required in elastic steel

The performance characteristics of the elastic parts are subjected to static load and high impact but are not allowed to be plastic deformed. With such characteristics in addition to the appropriate shape, the elastic steel must also achieve the following factors:

– High elasticity limits, ie resistance to high deformation, should be as close to 1 as possible, usually within the range 0.85 – 0.95.

– High hardness in HRC range 35 – 45 or HB 350 – 450 is appropriate; plasticity, low toughness to avoid any excess deformation during work, but not too low to be crushed easily.

– High fatigue limits to accommodate changing load conditions.

Steel grades used to make saws

The steel used to make knives, blades such as 65Mn, 60 Si2Mn, 60Si2MnA, 55CrMnA, 60CrMnA, 50CrVA, 60Si2CrA, 28MnSiB standard GB. Some grades of steel are produced according to JIS and EN standards as S65C, SUP7, SUP9, SUP9A, SUP10, C60E, 61SiCr7, 55Cr3, 60Cr3, 51CrV4, 54 SiCr6

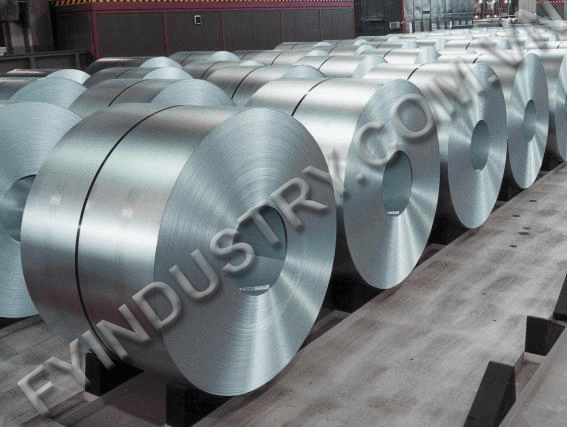

These types of steel need to achieve technical features such as 40-50 HRC hardness that is suitable for saw blades, industrial knives and other saw blades. The type of elastic steel purchased to make quality knives is usually elastic tape, belt, elastic band

Immediately see the standard sizes of elastic steel at factory prices

In addition, the steel cutting tools must also have certain technology.

– Good permeability to ensure high hardness and uniformity when I in the oil, especially the knife has a complex shape like milling, drill … I have to classify to avoid cracking and deformation.

– Ability to work under pressure in hot state.

– Ability to work in the cutting state

– Good grinding after me.

In addition to making knives, saw blades, cutting materials with high hardness, wind steel is the type of steel used to replace the perfect for the elastic steel. Because the characteristics of this steel is very hard can cut the diamond

Find more information on steel grades and chemical composition of wind turbines

Above are some of the information that you may be interested in purchasing elastic steel making quality saws. Hope the article has brought interesting and meaningful information to readers